Heavy-Duty Performance for Maine’s Toughest Bulk Material Handling Environments

In the aggregate industry, belt reliability is everything. Whether you’re moving crushed stone, gravel, sand, or other high-load materials, your conveyor belts must endure extreme conditions—abrasion, impact, and heavy throughput—without stretching, slipping, or failing.

That’s why aggregate producers throughout Maine trust PRC Industrial and the Legg Legend™ line of industrial conveyor belts. Built for long-term performance in some of the harshest environments, Legend belts combine rugged construction, excellent tracking, and consistent tension performance—all with fast availability and expert support from PRC Industrial.

Built for Demanding Aggregate Applications

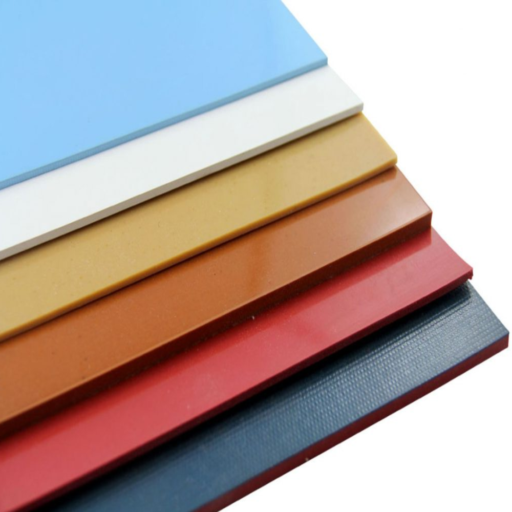

The Legend™ line from Legg Belting is engineered with high-performance polyester warp and either polyester or nylon fill yarns. This all-fabric carcass structure provides a powerful combination of strength, flexibility, and low stretch—exactly what aggregate operations require when running high-tonnage conveyors across large facilities.

Key construction advantages include:

- Polyester warp yarns – Deliver excellent tensile strength with minimal stretch, especially beneficial where take-up is limited.

- Nylon or polyester fill yarns – Enhance lateral stability, rip resistance, and load support.

- S&Z twist construction – Provides superior tracking and minimal cupping across long runs and aggressive conditions.

- Hot vulcanization compatibility – Ideal for belt splicing and fabrication in demanding field applications.

Why Legend™ Belts Are Perfect for Aggregate Producers

- Handles heavy loads with ease – Available in multiple PIW (pounds per inch of width) ratings from 80 to 1250 PIW, Legend belts accommodate light screening to heavy crushing operations.

- Resists ripping and tearing – Reinforced with durable skims and tough fill yarns, this belt is built for conveyors that face sharp aggregate and high impact.

- Excellent tracking and tension stability – Reduces maintenance and downtime caused by belt misalignment or stretching under load.

- Performs in severe environments – Moisture-resistant, heat-resistant, and chemical-resistant carcass construction ensures long life in outdoor and abrasive aggregate conditions.

Popular Legend™ Belt Specs for Aggregate Use

Depending on your application (load weight, conveyor length, idler setup, and trough angle), PRC Industrial can recommend the best Legend™ belt configuration for your operation. Common options include:

- 2/250, 3/375, 4/500, 5/625 PIW ratings – Ideal for medium- to heavy-duty bulk conveying across standard 20°, 35°, or 45° troughs

- Legend 225 and 250 – Polyester/Nylon construction for maximum impact resistance and flexibility

- Legend 300 to 1250 PIW – Heavy-duty Legend belts built for rock, gravel, and oversized material where extreme load support and long life are essential

- Minimum pulley diameters ranging from 12″ to 36″, allowing compatibility with a wide range of existing conveyor systems

Maine’s Local Source for High-Performance Conveyor Belts

As an authorized distributor of Legg Belting products, PRC Industrial offers:

- Expert product selection and sizing

- Belt customization and fabrication

- Emergency belt replacements and field splicing

- On-site support for aggregate producers across Maine and the Northeast

We work closely with quarries, sand pits, crushing operations, and concrete plants to ensure your belts are not only up to the task—but built to last.

Ready to Upgrade Your Aggregate Conveyor Belts?

Contact PRC Industrial today to get matched with the right Legend™ belt for your quarry, pit, or crushing plant. We’ll help you select the optimal configuration for strength, tension, and belt life—backed by the local support and service that keeps your operation moving.