Proper hose installation is critical to the safety, performance, and longevity of any industrial or hydraulic system. One of the most overlooked—but essential—factors in hose performance is minimum bend radius. Ignoring this specification can lead to system inefficiencies, premature hose failure, and safety hazards.

What Is Minimum Bend Radius and Why Does It Matter?

The minimum bend radius refers to the tightest curve a hose can make without causing internal damage or restricting flow. Bending a hose too tightly can result in:

- Restricted flow – Kinks reduce system efficiency and increase pressure buildup.

- Structural weakening – Repeated or excessive bending stresses the hose reinforcement and leads to degradation.

- Leaks and ruptures – Over time, improper bending can cause cracks or full hose failure, creating downtime and safety risks.

What Affects Minimum Bend Radius?

Several factors influence a hose’s bendability and overall performance:

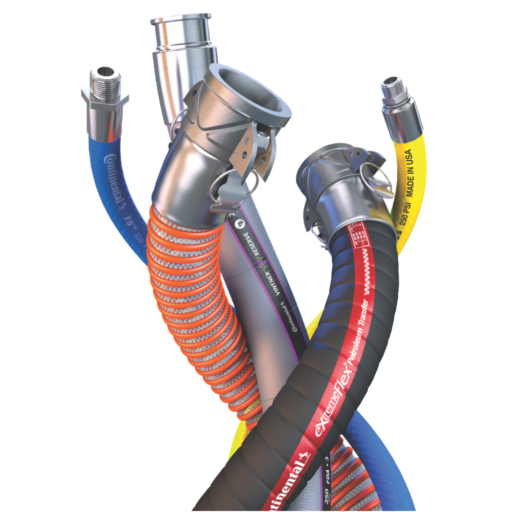

- Material type – Rubber hoses are generally more flexible, while metal or thermoplastic hoses need larger bend radii.

- Reinforcement construction – Braided hoses are more flexible than spiral-wound hoses, which are stiffer but often rated for higher pressures.

- Operating temperature – Heat can soften hose material; cold can make it brittle or stiff, affecting how tightly it can bend.

- Pressure rating – Hoses rated for higher pressure often require a larger bend radius to prevent structural failure under stress.

Best Practices for Hose Installation

To ensure optimal hose performance and lifespan, follow these guidelines during installation:

- Use the largest bend radius possible – Avoid forcing hoses into tight bends. Let them curve naturally.

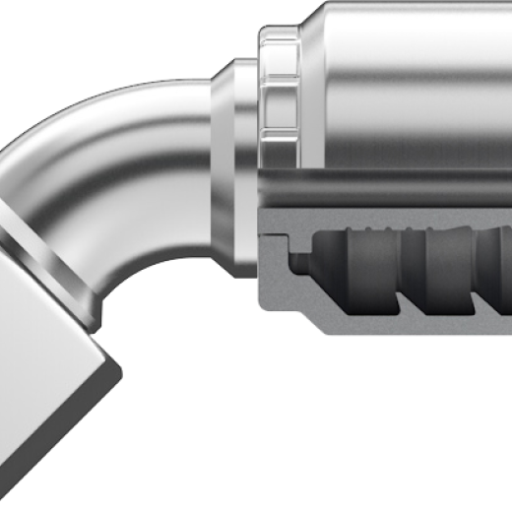

- Avoid sharp bends near fittings – Maintain a straight section of at least 18 inches before any bends to reduce stress on the connection.

- Use hose supports and clamps – Secure hoses to avoid sagging, kinking, or unnecessary movement.

- Factor in system temperature and pressure – Choose hoses that are rated appropriately for your operating conditions.

- Conduct regular inspections – Look for wear, cracking, leaks, or signs of bending stress before a failure occurs.

Need Help Choosing the Right Hose?

Selecting the right hose and installing it correctly can significantly improve safety, efficiency, and equipment lifespan. At PRC Industrial, our team provides expert support and access to a full range of hoses engineered for demanding environments.

Contact PRC Industrial today to speak with a hose specialist and get tailored recommendations for your specific application.