Choosing the right chemical-resistant hose is critical to maintaining safety, reliability, and productivity in industrial environments. The wrong hose choice can lead to chemical breakdown, premature failure, and costly unplanned downtime. To avoid these issues, it’s important to evaluate several key selection criteria, steer clear of common missteps, and follow best practices that promote long-term performance.

Key Considerations When Choosing a Chemical Hose

Before selecting a hose for chemical service, consider the following:

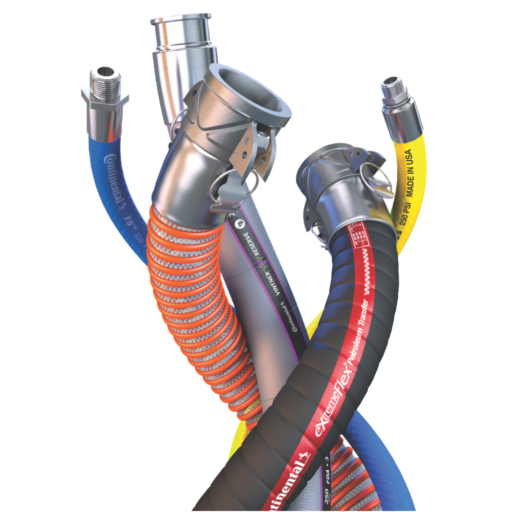

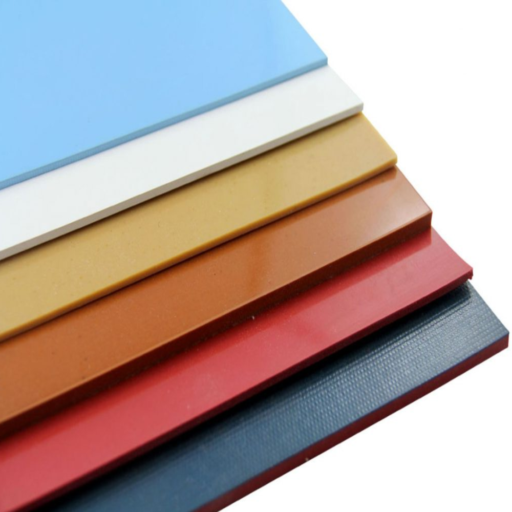

- Is the hose material compatible with your chemicals?

Different materials offer varying levels of chemical resistance. Options like PTFE, rubber, stainless steel, and composite each perform differently depending on the media. Always consult a chemical compatibility chart to confirm the best match. - Can the hose handle your temperature range?

High or fluctuating temperatures can degrade hose materials and lower pressure ratings. Select a hose built to perform under your system’s thermal conditions. - Does the hose meet your pressure requirements?

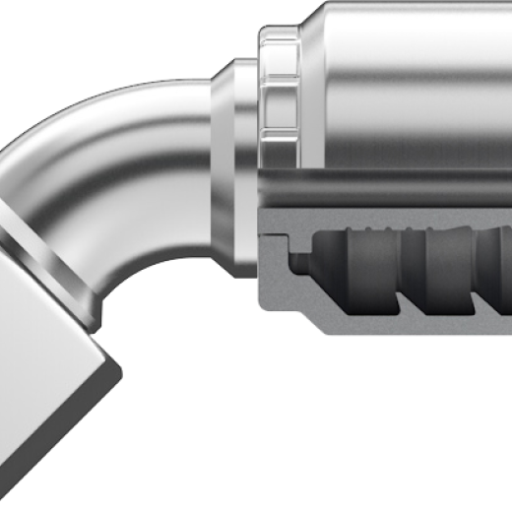

Verify that the hose can safely withstand both the working and burst pressures of your application to prevent dangerous failures. - Do you need flexibility?

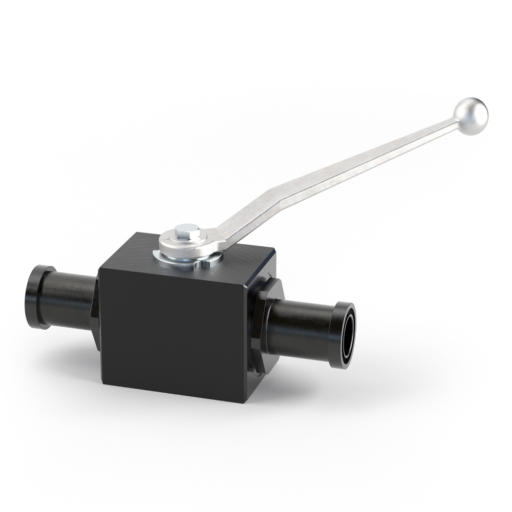

Improper bend radius can lead to kinking, internal damage, and early wear. Choose a hose designed with the right level of flexibility for your layout. - Is static conductivity a factor?

When static buildup poses a risk, choose a conductive hose and ensure proper grounding to reduce the chance of static discharge. - Does the hose size and length suit your system?

An undersized or oversized hose can impair flow, increase pressure drop, and create unnecessary hazards.

Common Mistakes to Avoid

- Ignoring chemical compatibility – Using the wrong hose for a chemical can lead to leaks, hose breakdown, and contamination.

- Disregarding temperature ratings – Extreme conditions can cause unexpected degradation.

- Mismatched pressure ratings – A hose rated too low may burst during normal operation.

- Skipping routine inspections – Regular checks can catch damage early and prevent failures in the field.

Tips to Extend Hose Lifespan

- Perform regular inspections – Look for wear indicators like cracks, bulges, leaks, or soft spots before each use.

- Store hoses correctly – Keep hoses in a clean, dry, temperature-controlled area away from sunlight and corrosive substances.

- Install properly – Avoid sharp bends, stretching, or twisting during setup, all of which can weaken the hose structure.

- Clean thoroughly and often – Follow flushing and cleaning protocols to prevent chemical buildup and cross-contamination.

Partner with PRC Industrial for the Right Hose Solution

Selecting the correct chemical-resistant hose isn’t just about performance—it’s a matter of safety. At PRC Industrial, we offer expert support and premium industrial hose products designed to meet the demands of chemical transfer applications. Contact PRC Industrial today for tailored solutions and dependable chemical hose options backed by trusted industry experience.