Dust suppression is a critical priority in aggregate mining operations. It directly impacts worker health and safety, equipment performance, and regulatory compliance. Silica dust, in particular, presents significant long-term health hazards and is tightly regulated by OSHA and other agencies. At PRC Industrial, we partner with Benetech to deliver advanced dust suppression systems that help aggregate producers across the Northeast operate more safely, efficiently, and in full compliance with air quality standards.

Understanding the Risks of Silica Dust Exposure

Crystalline silica dust is released during crushing, grinding, and material handling. Over time, exposure to fine respirable particles can cause irreversible damage to the respiratory system.

Common health risks include:

- Silicosis (lung scarring and breathing difficulties)

- Lung cancer

- Chronic Obstructive Pulmonary Disease (COPD)

To mitigate these risks, OSHA limits worker exposure to respirable crystalline silica at 50 micrograms per cubic meter over an 8-hour shift. Failing to control silica dust can result in serious penalties, legal exposure, and worker injury.

Benetech Solutions: Engineered for Control and Compliance

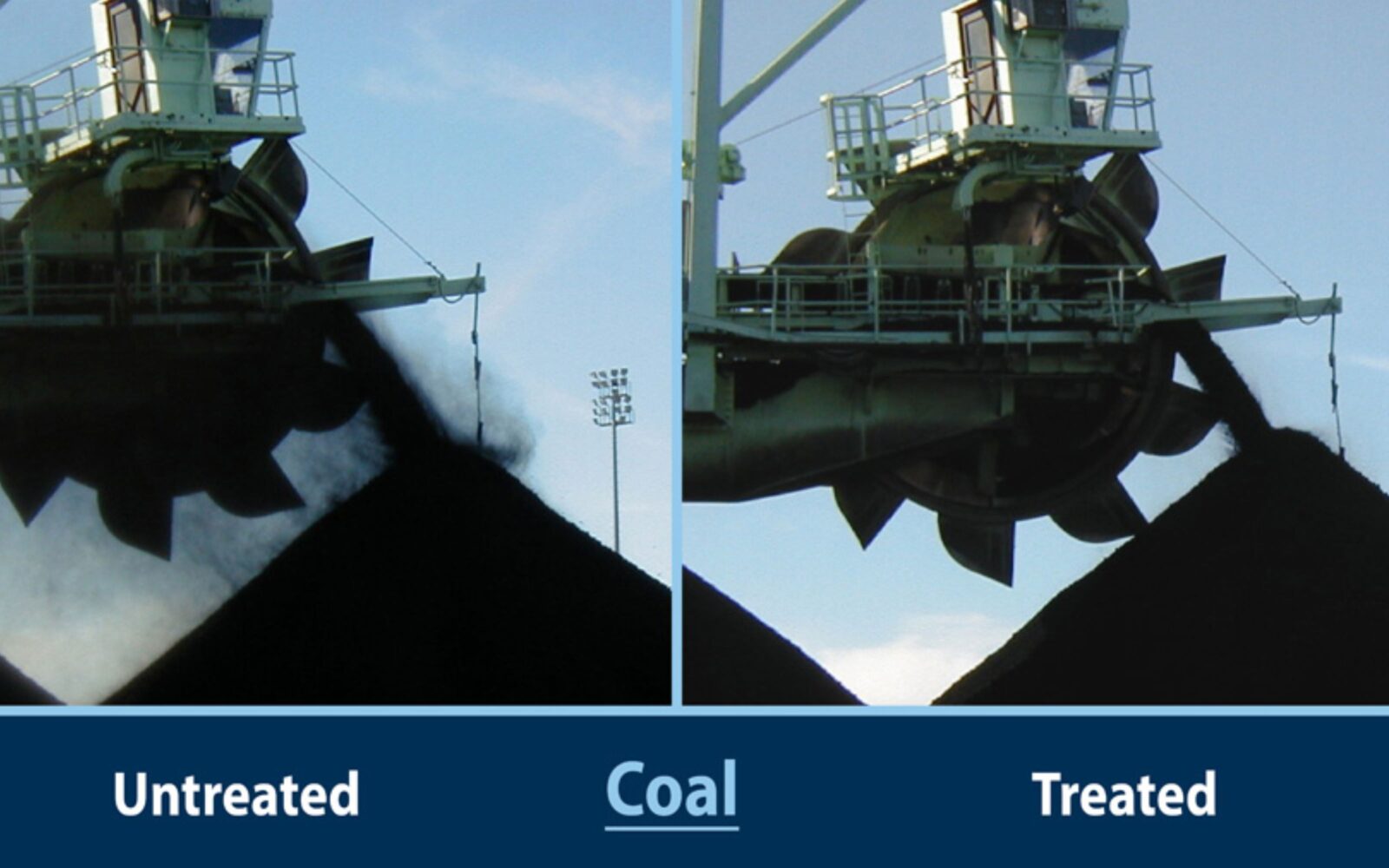

Benetech dust suppression systems are designed to capture airborne dust at the source, reduce emissions, and improve site conditions across the board.

Key system options include:

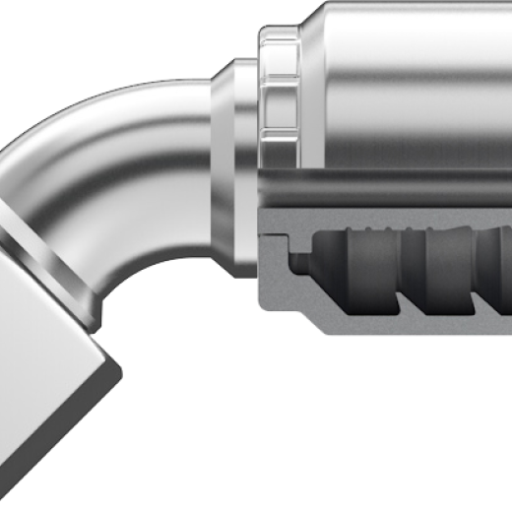

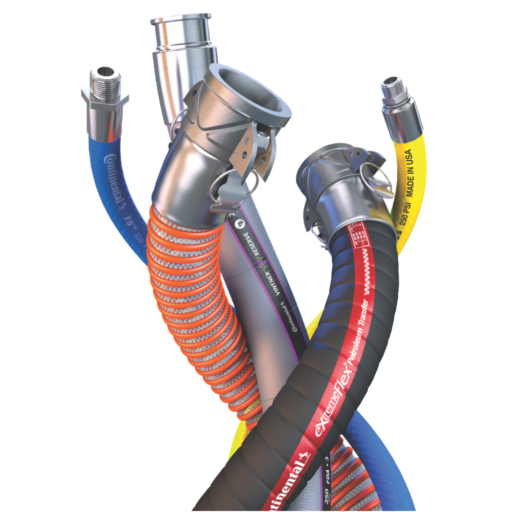

- Wet Dust Suppression Systems – Water misting and spray nozzles for crushers, conveyor belts, and material transfer points.

- Foam Suppression Systems – Encapsulates fine dust with a foam blanket, offering effective control with reduced water usage.

- Chemical Dust Control – Water-enhancing agents improve dust binding and prevent material buildup in critical areas.

- Enclosed Transfer Point Solutions – Dust curtains, belt skirting, and enclosure systems that keep dust from escaping into the work environment.

Benefits of Benetech Dust Suppression Systems

Implementing Benetech systems with PRC Industrial offers measurable improvements in workplace safety, environmental compliance, and operational efficiency:

- Protects worker health by reducing silica dust exposure

- Extends equipment life by minimizing dust buildup on conveyors and crushers

- Improves visibility and on-site safety by reducing airborne dust clouds

- Helps ensure compliance with OSHA, MSHA, and EPA air quality standards

- Reduces maintenance, cleanup, and unplanned downtime

Frequently Asked Questions

Q: What’s the best type of suppression system for my site?

A: It depends on your material, equipment layout, and dust generation points. PRC can help evaluate your site and recommend a wet, foam, or chemical system—or a combination.

Q: Will suppression systems increase water usage?

A: Not necessarily. Foam and chemical-based systems often use far less water than traditional misting, making them more sustainable and cost-effective.

Q: How quickly can these systems be implemented?

A: Most systems can be integrated into your existing material handling infrastructure with minimal downtime. PRC works closely with Benetech to ensure timely delivery and setup.

Q: Can this help reduce cleanup labor and equipment maintenance?

A: Yes. By controlling dust at the source, you’ll reduce accumulation on motors, belts, and bearings—leading to less frequent maintenance and improved equipment lifespan.

Why PRC Industrial?

PRC Industrial brings deep experience in industrial hose, conveyor components, and site safety solutions. By partnering with Benetech, we deliver custom-engineered dust control systems backed by field-proven results.

- Local support and inventory in the Northeast

- On-site evaluations and tailored recommendations

- Expert implementation and after-sale support

- Full compliance with industry safety and air quality standards

Looking to protect your people and your equipment with an effective dust suppression system? Contact PRC Industrial today to schedule a consultation or request a quote for Benetech dust control solutions.