Why PRC Industrial is the First Choice for Advisory and Supply

Recycling facilities place unique demands on conveyor belts—abrasive materials, variable loads, and high-impact zones can quickly wear down systems not designed for the job. Choosing the right belt is essential not just for performance, but for safety, efficiency, and long-term cost control.

At PRC Industrial, we help recycling operations across the Northeast select and maintain conveyor belts engineered specifically for material recovery, processing, and waste handling.

What Makes Recycling Conveyor Systems Different?

Recycling operations often involve handling a wide range of materials under demanding conditions. These systems must be able to:

- Withstand exposure to sharp, irregular, or abrasive debris

- Handle fluctuating load weights and impact zones

- Resists oil, grease, and chemical contamination

- Operate in environments with high dust or moisture

- Maintain alignment through frequent starts, stops, and directional changes

A belt that works in a quarry or food plant may not hold up in a recycling facility—belt selection needs to reflect these unique operational challenges.

Key Factors in Selecting a Recycling Conveyor Belt

1. Material Type and Characteristics

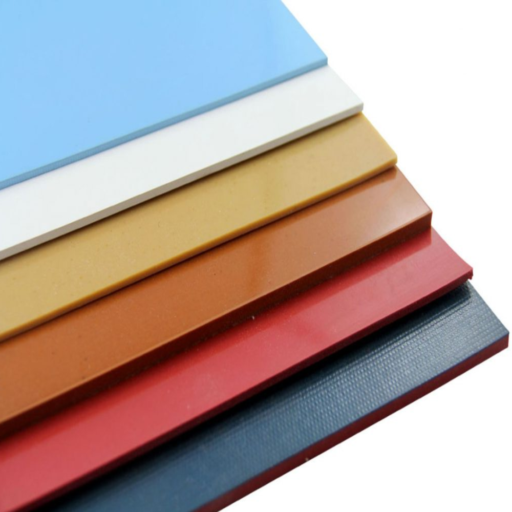

From shredded plastics and cardboard to scrap metal and glass, each material poses different wear and impact challenges. Understanding the type, weight, and shape of materials is the first step in selecting a suitable belt.

2. Abrasion and Cut Resistance

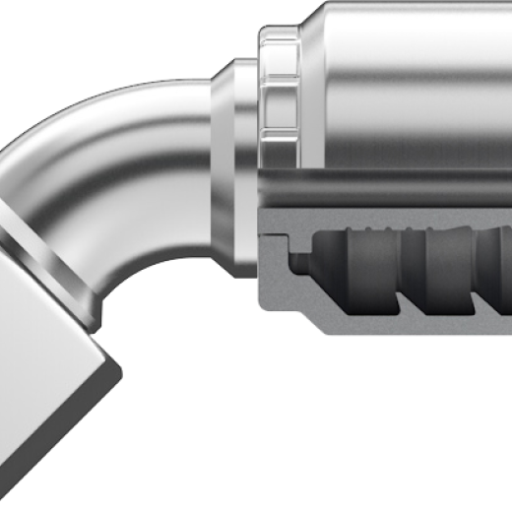

Recycling systems often process broken or jagged materials. A belt with reinforced covers, fabric plies, or steel reinforcements may be needed to resist cutting, tearing, or gouging.

3. Oil and Chemical Resistance

Materials like motor oil, lubricants, or chemical containers can deteriorate standard rubber compounds. Oil-resistant and chemical-resistant belts are essential for mixed-waste processing environments.

4. Impact Resistance

Drop zones and loading areas experience high impact from heavy or fast-moving material. Belts with impact-resistant inner plies or shock-absorbing top covers can prevent premature failure.

5. Temperature and Environmental Conditions

Outdoor facilities or transfer stations may expose belts to extreme cold, heat, or moisture. Selecting belts that retain flexibility and strength in those conditions is critical to maintaining uptime.

6. System Configuration and Speed

Inclines, declines, belt scrapers, and side guards must be considered when selecting the belt cover type, thickness, and surface texture (e.g., smooth, cleated, or rough-top).

Why PRC Industrial Is the Preferred Conveyor Belt Partner

Recycling operators across the Northeast trust PRC Industrial because we provide more than just belts—we deliver solutions.

Application-Specific Expertise

Our team understands the demands of recycling systems. We evaluate each application and recommend belts tailored for material type, environment, and system configuration.

Access to Premium Belt Lines

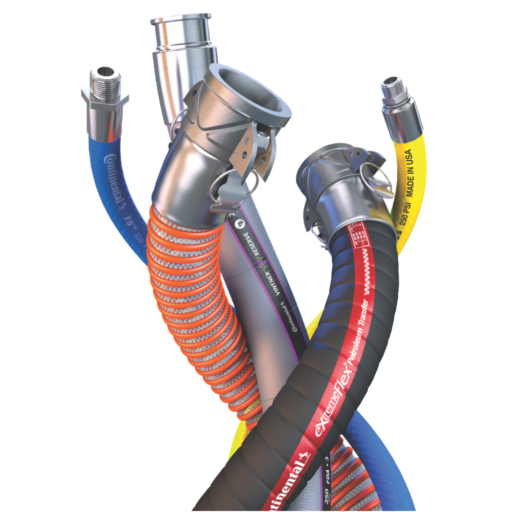

We offer a wide range of belts from leading manufacturers designed for recycling and waste handling. From rubber multi-ply belts to specialty cleated, steel cable-reinforced, or impact-resistant options, we match the right product to your system.

On-Site Technical Support

We don’t just ship product—we support installation, troubleshooting, and long-term maintenance strategies. Our field service team can conduct on-site assessments, belt tracking, and emergency repair when needed.

Custom Fabrication & Fast Turnaround

Need a custom-cleated belt, endless splice, or sidewall installation? PRC Industrial offers in-house belt fabrication with short lead times to minimize your downtime.

Long-Term Cost Control

Our goal is to help facilities reduce unplanned maintenance, extend belt life, and improve system reliability. That means fewer breakdowns, better throughput, and less budget lost to reactive repairs.

Need Help Choosing the Right Belt for Your Recycling Operation?

If you’re dealing with premature belt failure, excessive downtime, or simply need expert guidance on the best belt for your recycling system, PRC Industrial is ready to help.

Contact us today to schedule a site visit, speak with a conveyor specialist, or request a quote on engineered belt solutions for your recycling application.