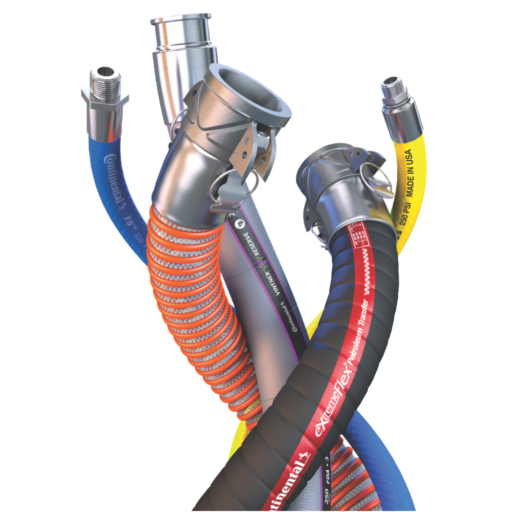

Extend Hose Life, Improve Safety, and Reduce Downtime

Hose failure can create serious safety hazards, interrupt operations, and result in costly repairs or equipment damage. At PRC Industrial, we help our customers understand the leading causes of hose failure—and how to prevent them. With the right products, installation practices, and maintenance routines, you can dramatically extend hose life and maintain reliable system performance.

Top Causes of Hose Failure & How to Prevent Them

1. Abrasion and External Damage

- Cause: Hoses that rub against equipment, concrete, or sharp edges suffer surface wear that leads to early failure.

- Prevention:

- Use abrasion-resistant sleeves or protective guards.

- Route hoses away from high-friction or high-contact areas.

- Use abrasion-resistant sleeves or protective guards.

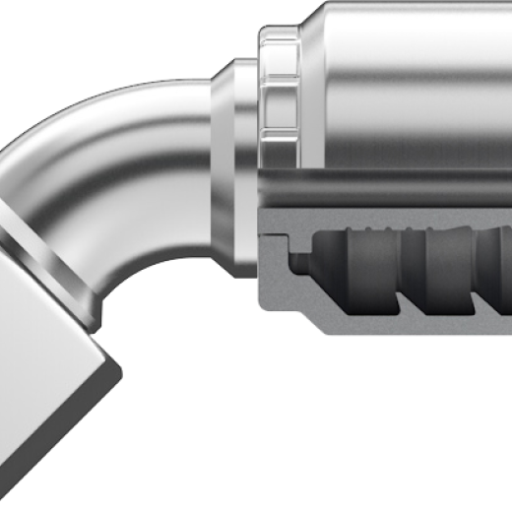

2. Improper Bend Radius

- Cause: Tight bends kink the hose, restricting flow and stressing reinforcement layers.

- Prevention:

- Follow manufacturer bend radius specifications.

- Use clamps or guides to maintain a proper hose curve and prevent collapse.

- Follow manufacturer bend radius specifications.

3. Extreme Temperatures

- Cause: Heat degrades hose compounds; cold causes stiffening and cracking.

- Prevention:

- Select hoses designed for your temperature range (high-temp or cold-flex rated).

- Store hoses in temperature-controlled environments when not in use.

- Select hoses designed for your temperature range (high-temp or cold-flex rated).

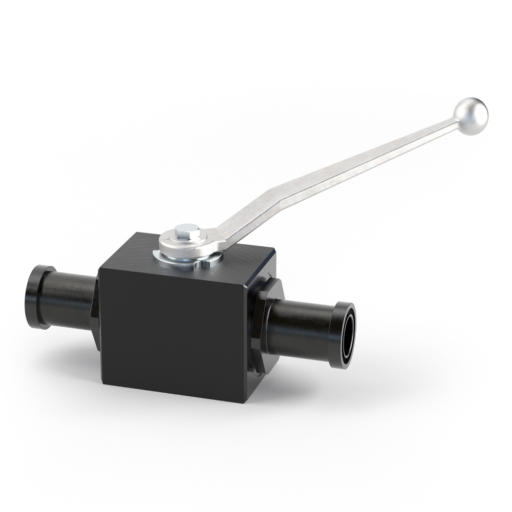

4. Pressure Surges and Overloading

- Cause: Rapid pressure spikes or operation above rated working pressure can cause sudden failure.

- Prevention:

- Install pressure regulators or relief valves.

- Choose hoses with appropriate working and burst pressure ratings.

- Open and close valves gradually to minimize system shock.

- Install pressure regulators or relief valves.

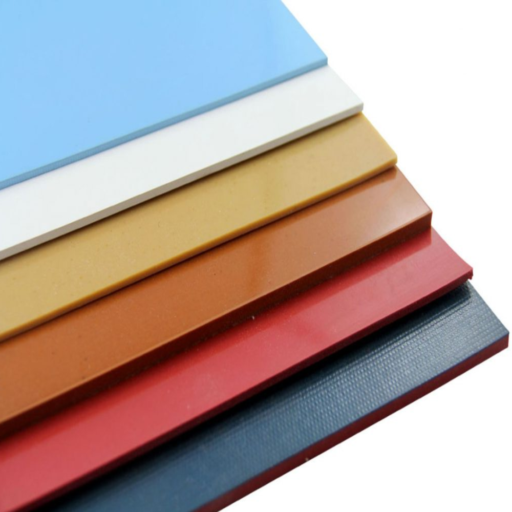

5. Chemical Incompatibility

- Cause: Certain chemicals degrade hose material, leading to cracks, swelling, or leaks.

- Prevention:

- Check chemical compatibility charts before selecting a hose.

- Use hoses made with chemically resistant materials such as PTFE, EPDM, or UHMW.

- Check chemical compatibility charts before selecting a hose.

6. Poor Installation Practices

- Cause: Twisting during installation, over-tightening fittings, or improper routing can compromise hose integrity.

- Prevention:

- Train teams on best installation practices.

- Avoid stretching or pulling hoses during setup.

- Secure hoses properly to reduce mechanical strain.

- Train teams on best installation practices.

Proactive Maintenance Tips to Prevent Hose Failures

Preventing hose failure doesn’t stop at installation—routine maintenance plays a major role in extending hose life and protecting your operation.

- Perform regular visual inspections – Look for signs of wear, leaks, or damage before every use.

- Pressure test hoses on a scheduled basis – Identify potential weak points before a failure occurs.

- Replace worn or aging hoses proactively – Waiting until failure can result in unplanned downtime and safety risks.

Need a Hose Failure Analysis or Preventative Maintenance Plan?

PRC Industrial offers professional hose testing, failure analysis, and custom maintenance programs to help companies reduce hose-related failures and improve system reliability. Our team of experts can evaluate your current hose setup and recommend solutions tailored to your specific applications.

Contact PRC Industrial today to schedule a hose evaluation or learn more about our preventative maintenance services.