Optimize Uptime, Safety, and System Lifespan

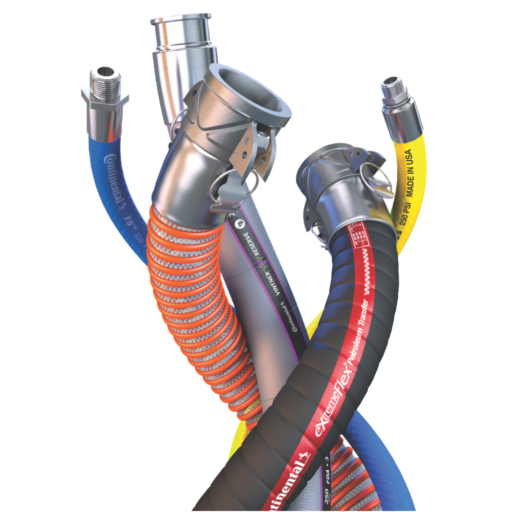

Conveyor systems are the backbone of aggregate, mining, manufacturing, and bulk material handling operations. When a belt goes down, so does productivity. At PRC Industrial, we work with facilities across the Northeast to implement proactive conveyor belt maintenance programs that reduce unplanned downtime, improve safety, and extend system life.

Here are the key best practices every facility should follow to keep conveyor belts operating at peak performance.

1. Conduct Routine Visual Inspections

Regular walk-through inspections can reveal early signs of wear, misalignment, or contamination. Look for:

- Cracks, cuts, or gouges in the belt surface

- Worn or missing lagging on pulleys

- Misaligned or slipping belts

- Material buildup on rollers or return idlers

- Frayed edges or uneven belt tracking

Catch small problems before they become costly failures.

2. Check Belt Tension and Alignment

Improper belt tension can lead to slippage, premature wear, and tracking issues. Belt alignment is equally critical to avoid edge damage and mistracking.

- Use proper tools to measure tension

- Adjust take-up units evenly

- Monitor tracking during startup and under load

- Correct any pulley or roller misalignment that contributes to drift

3. Keep Belts and Components Clean

Debris and buildup can damage belts, overload motors, and reduce efficiency. Regularly clean:

- Belt surface to remove fines and residue

- Pulleys, rollers, and idlers to ensure smooth rotation

- Skirtboards and chutes to prevent material overflow

Consider installing belt cleaners, plows, or belt washing systems in high-debris areas.

4. Lubricate Bearings and Moving Parts

Neglected bearings can seize, overheat, or cause belt-tracking problems. Follow a lubrication schedule for:

- Idlers and return rollers

- Pulley bearings

- Drive components

Use the manufacturer’s recommended lubricant and avoid over-greasing, which can attract dirt and cause failure.

5. Monitor Splices and Joints

Whether mechanical or vulcanized, splices are a critical part of the belt’s integrity.

- Inspect regularly for separation, fraying, or wear

- Use proper tools and techniques for new splice installation

- Avoid overloading or shock loads that can stress splice areas

Poor splicing is one of the top causes of belt failure—attention here pays off long-term.

6. Replace Worn Components Before Failure

Don’t wait for a catastrophic breakdown. Monitor wear items such as:

- Idlers and rollers

- Scrapers and cleaners

- Skirting and sealing systems

- Lagging on drive pulleys

Schedule proactive replacements during planned maintenance windows to avoid downtime during peak operations.

7. Keep Detailed Maintenance Records

Track belt service history, tensioning adjustments, splice replacements, and component swaps. This data helps:

- Identify recurring issues

- Plan future replacements

- Make informed decisions about upgrades or redesigns

Well-documented maintenance improves system reliability and planning accuracy.

Partner with PRC Industrial for Conveyor Support

PRC Industrial supplies the conveyor belts, components, and field support your operation needs to stay productive. Our team provides:

- Belt inspections and condition monitoring

- Splicing and installation services

- Cleaner and skirting system upgrades

- Emergency repair support across the Northeast

Whether you’re managing a quarry, plant, or terminal, we help you stay ahead of maintenance issues and keep your system moving.

Need a conveyor belt assessment or parts support?

Contact PRC Industrial today to schedule a site visit or speak with a conveyor specialist.