In industrial and hydraulic systems, proper hose selection and installation are vital for safe and efficient operation. One of the most overlooked—but critical—factors affecting hose performance is minimum bend radius. Ignoring it can lead to premature failure, restricted flow, or even dangerous system breakdowns.

What Is Minimum Bend Radius and Why Does It Matter?

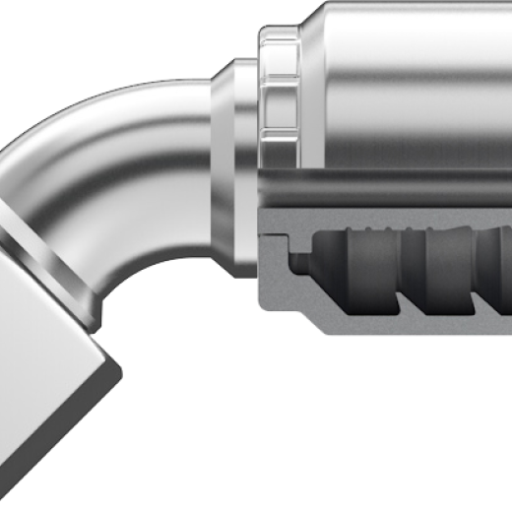

Minimum bend radius is the tightest curve a hose can safely be bent without compromising its integrity. Bending a hose beyond this limit can cause:

- Restricted flow – Kinking reduces fluid movement and increases pressure buildup.

- Structural weakening – Overbending damages internal reinforcement layers.

- Leaks and ruptures – Repeated stress causes cracks or bursts, posing safety hazards and triggering downtime.

Key Factors That Influence Minimum Bend Radius

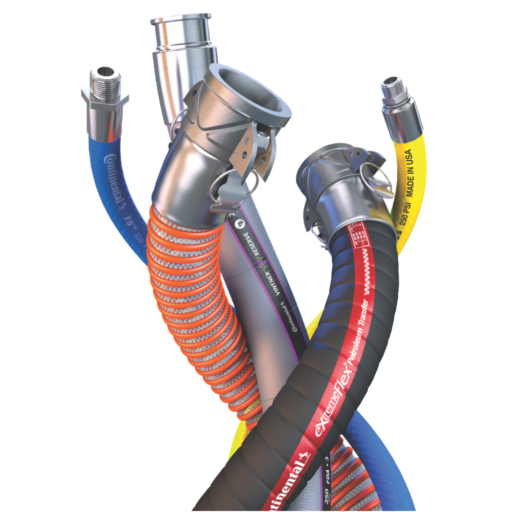

- Material type – Rubber hoses are more flexible, while thermoplastic and metal hoses require larger bend radii.

- Reinforcement construction – Braided hoses offer more flexibility than spiral-reinforced designs.

- Operating temperature – Heat softens hose materials; cold makes them stiff and less bendable.

- Pressure rating – Higher-pressure hoses often need larger bend radii to handle internal stress.

Best Practices for Hose Installation

- Use the largest bend radius possible – Avoid forcing tight turns or unnatural curves.

- Avoid sharp bends near fittings – Maintain at least 18 inches of straight hose before any bend.

- Install hose supports or clamps – Prevent excessive bending or sagging in horizontal runs.

- Choose hoses rated for your system – Factor in both temperature and pressure conditions.

- Inspect hoses regularly – Look for early signs of damage before a failure occurs.

Maximizing Hose Lifespan: Care, Maintenance & Storage

Proactive maintenance improves system safety and reduces long-term costs. Extend hose life by following these best practices:

Hose Care and Maintenance

- Avoid excessive bending – Prevent structural fatigue by respecting bend radius limits.

- Manage temperature exposure – Verify hoses are rated for both media and environment.

- Control pressure surges – Open valves slowly to avoid pressure spikes.

- Confirm chemical compatibility – Mismatched hose materials can lead to rapid degradation.

- Protect hoses from UV and weather – Sunlight and moisture weaken outer hose covers over time.

Proper Hose Storage

- Store hoses in a cool, dry location – Avoid exposure to direct sunlight or temperature extremes.

- Use First-In, First-Out (FIFO) rotation – Prevent premature aging of stored hose inventory.

- Cap hose ends when not in use – Keep out dust, debris, and contaminants that damage inner linings.

Why Regular Inspections Are Essential

Routine inspections can prevent major failures by catching wear early. Be sure to check for:

- Cracks, bulges, leaks, or stiffness

- Loose or corroded fittings

- Signs of wear or chemical degradation

Need Help Managing Your Hose Inventory?

Keeping hoses in service-ready condition requires a plan. PRC Industrial offers hose management programs to help:

- Track hose maintenance and inspections

- Extend hose service life

- Minimize unplanned downtime and replacement costs

Contact PRC Industrial today to learn more about our custom hose management solutions and expert support services.