Categories

Categories

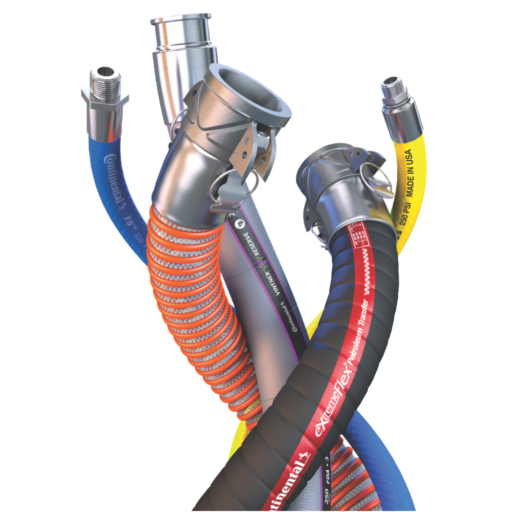

Water Discharge Hose

Water discharge hoses are designed for high-volume liquid transfer in construction, agriculture, and dewatering applications. Made from durable rubber or PVC, these hoses are lightweight, flexible, and resistant to weather and abrasion. They facilitate efficient water removal and handling in industrial settings, ensuring reliability in demanding environments.